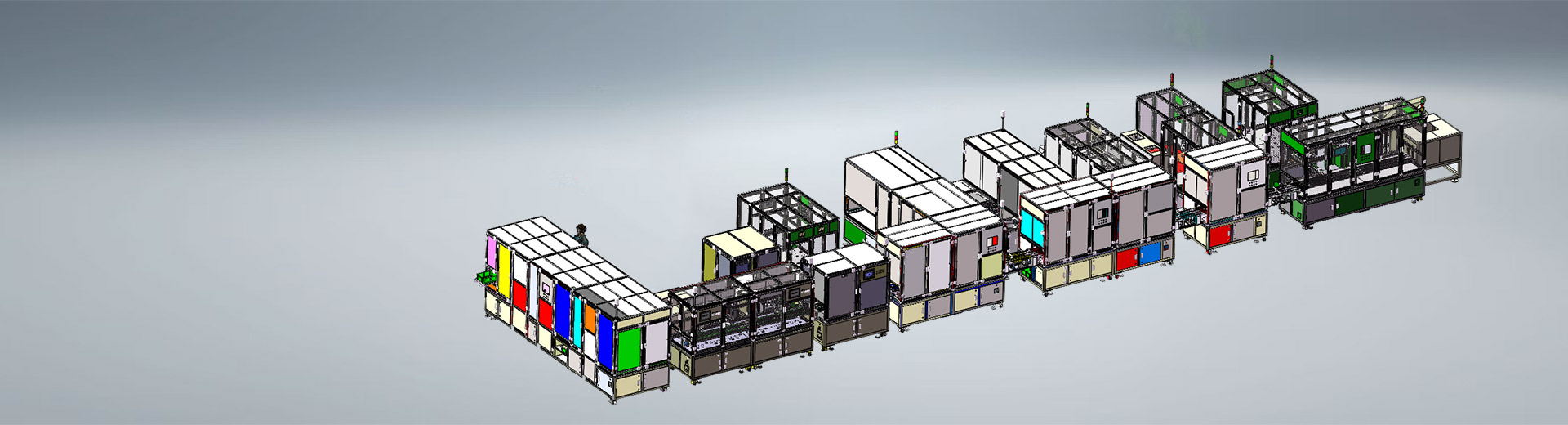

Mechanical Components Automated Welding Equipment

STIM DPN Mechanical Components Automatic Welding Assembly Equipment

Mechanical component automatic welding assembly equipment adopts advanced automation technology, combined with precision mechanical structure and intelligent control system, which can realize the efficient execution of complex welding processes and is widely used in automotive parts, aerospace, electronic manufacturing and other fields.

Core Features

High-precision welding: The equipment supports a variety of welding methods (such as spot welding, drag welding, girth welding, etc.), and is equipped with a high-precision linear motion system and a rigid casting frame to ensure high precision and stability during the welding process.

Modular design: With modular structure, the welding head, wire feeding mechanism and control system can be flexibly configured according to customer needs to meet the welding requirements of different products.

Intelligent control: equippedPLCProgrammable controller and servo drive system support digital control and recording of welding parameters, realizing automation and standardization of welding process.

Multifunctional integration: The equipment integrates welding, testing, cooling and other functions, reducing manual intervention and improving production efficiency and product quality.

Technical features

Flexible production: The equipment supports switching between multiple welding modes to meet the diverse needs of different products, and has good scalability and compatibility.

High efficiency and energy saving: Use advanced energy management technology to reduce energy consumption and extend equipment life.Safe and reliable: The equipment is designed in accordance with international safety standards and is equipped with multiple protection mechanisms to ensure the safety of operators.

Application

AreasAuto parts: suitable for body welding, parts assembly and other links.

Aerospace: used for welding and assembly of precision parts.

Electronic manufacturing: Support the insertion and welding of electronic components.

Energy and chemical industry: suitable for pipeline welding, heat exchanger assembly, etc.

Advantages

Improve production efficiency: Automated welding reduces manual operations and significantly improves production efficiency.

Reduce production costs: Reduce production costs by optimizing welding processes and reducing scrap rates.

Improve product quality: The high precision and stability of the equipment ensure the consistency and reliability of welding quality.

Technical support and service: We provide comprehensive technical support and after-sales service to ensure customers have no worries.

English

English Español

Español