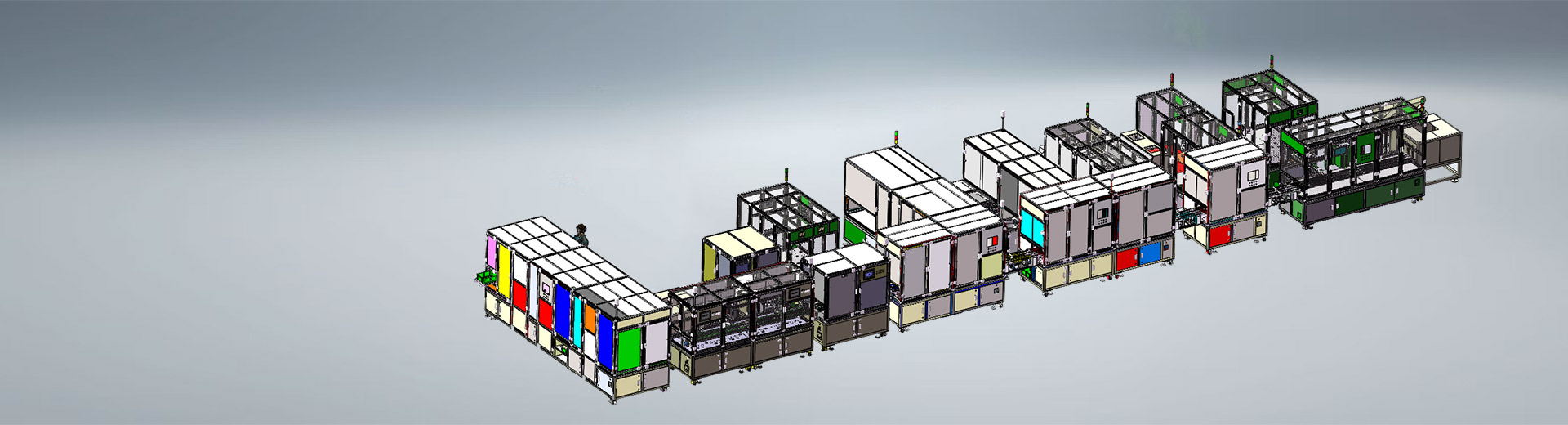

Fully Automatic Riveting Equipment

CNC Electric Screw Machine

Features

High precision and efficiency: The CNC screw machine adopts advanced CNC technology, which can achieve high-precision screw processing and installation, and is suitable for the manufacture of screws with various complex shapes and precision requirements.

Diversified functions: The equipment supports the processing of various screw specifications and materials, including stainless steel screws, carbon steel screws, galvanized screws, etc., to meet the needs of different application scenarios.

High degree of automation: equipped with functions such as automatic nail feeding and automatic locking, which significantly improves production efficiency, reduces manual intervention and reduces production costs.

Wide range of applications: suitable for elevator button panels, bathroom plumbing, steel structures, high-carbon steel and other scenarios, meeting the diverse needs of the industrial and construction fields.

Technical Parameters

Screw specification: support M2 to M34 Processing screws of different specifications.

Material adaptability: It can process screws made of various materials such as stainless steel, carbon steel, galvanized, etc.

Operation mode: Supports multiple control modes such as pneumatic and double pulse to meet the needs of different production lines.

Production efficiency: A single machine can process thousands of screws per hour, greatly improving production efficiency.

Application Scenario

Mechanical manufacturing: used for assembling mechanical parts, such as fixing gears, bearings, etc.

Construction industry: used in steel structure installation, door and window fastening, etc.

Automobile manufacturing: used for body welding, parts fixing, etc.

Electronics industry: used for assembly and fixation of precision electronic equipment.

English

English Español

Español