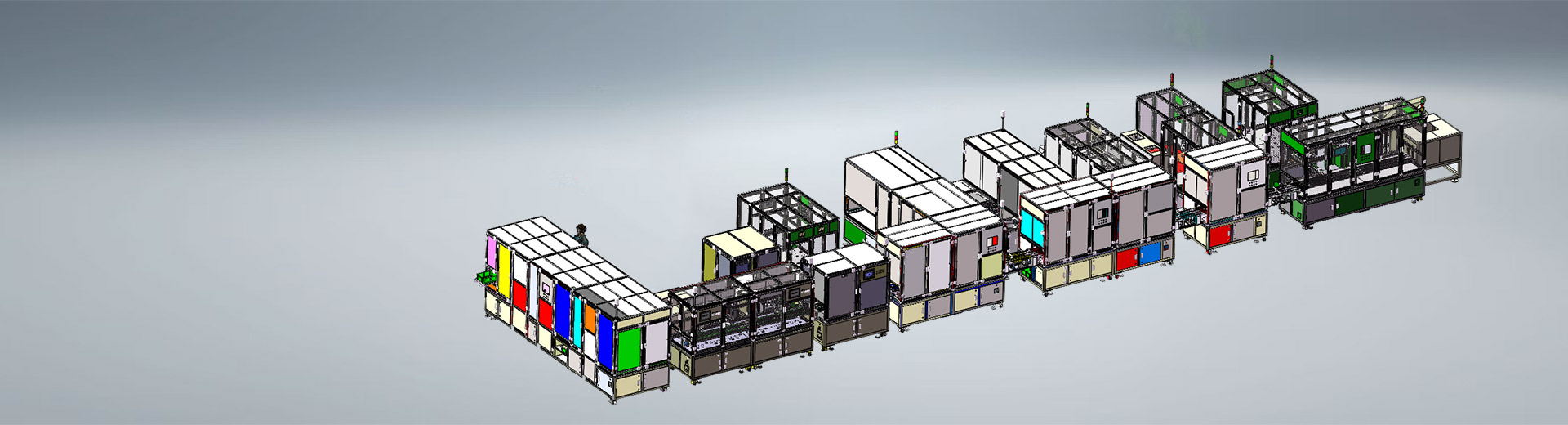

White Pole Automatic Assembly Production Line

STIM DPN Baiji White Pole Automatic Assembly Production Line

Features

Intelligent design: using advancedBIMTechnology supports one-click generation of production task orders, making the production process systematic and transparent.

Modular layout: The production line adopts a modular design, and the layout can be flexibly adjusted according to customer needs, supporting multiple combination modes from one-to-one to one-to-four.

Efficiency and stability: By combining tree structure, series structure and parallel structure, the production rhythm is optimized to ensure the continuity and stability of the production process.

High degree of automation: The automation rate of the whole line exceeds95%, significantly reducing labor costs while improving production efficiency and product quality pass rate.

Professionalism and customization: Provide customized solutions for different industries and product requirements to meet customers' personalized needs.

Technical highlights

Intelligent detection and feedback system: equipped with automatic detection module to monitor production status in real time to ensure that product quality meets standards

Energy management and environmental protection design: adopt high-standard dust removal and liquid injection technology to achieve green production.

Application Areas

STIM DPN BaijiWhite rod automatic assembly production lines are widely used in many industries such as automobiles, home appliances, lighting, batteries, etc., and are particularly suitable for scenarios that require high-precision and high-efficiency production.

English

English Español

Español