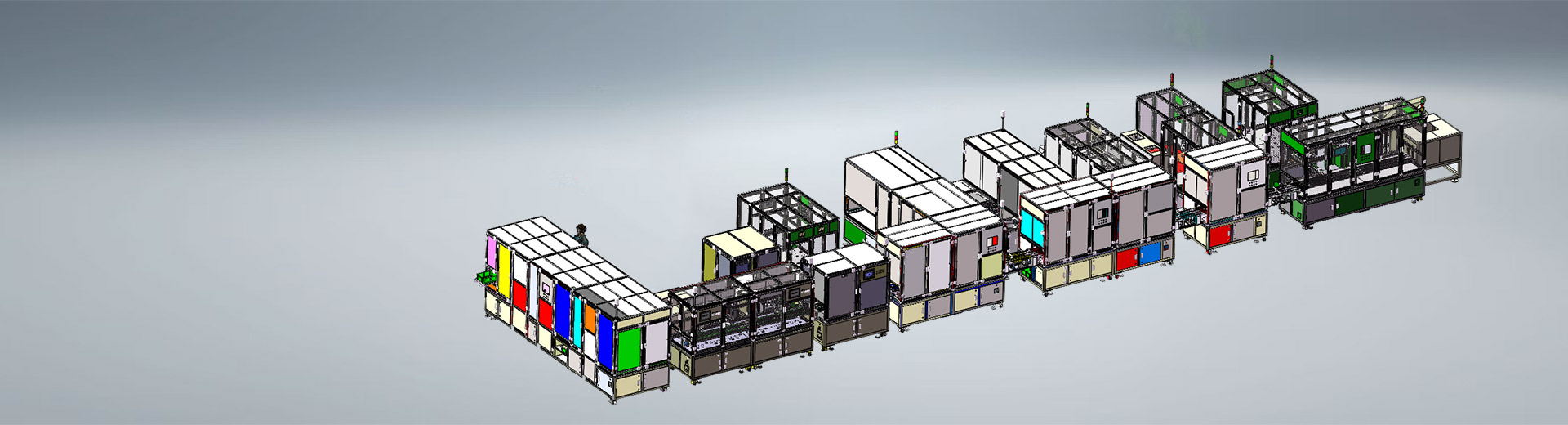

White Pole Automatic Assembly Production Line

TW DPN Baiji White Rod Automatic Assembly Production Line

High degree of automation: The entire production line adopts advanced automation technology, and each process can be carried out simultaneously, realizing full-process automation from raw material loading to finished product delivery, which greatly reduces labor costs and improves production efficiency.

Modular design: The production line adopts modular configuration, which can be flexibly combined and matched according to site restrictions and process requirements, supporting one-to-one to one-to-four production modes to adapt to production needs of different scales.

Intelligent management: Through the central control system, mutual control and network management between equipment are realized, supporting functions such as telemetry, telecommunication, and remote control to ensure stable operation and efficient management of the production line.

Accurate testing and quality control: Equipped with high-precision testing equipment to conduct real-time quality monitoring of products to ensure that each finished product meets high quality standards.

Flexible adjustment and scalability: The production line can be quickly adjusted according to changes in the production process and supports multiple devices to meet the customized needs of different customers.

Low labor intensity: A single production line only requires a small number of operators to complete production tasks, which significantly reduces labor intensity and improves production efficiency.

Wide applicability: This production line is suitable for the production needs of a variety of industries and products, including but not limited to electronics, automotive parts, smart home and other fields.

Customized service: Provide one-stop service from design to delivery according to customer needs, ensuring that customers can obtain personalized solutions that meet their technical requirements and quality standards.

English

English Español

Español