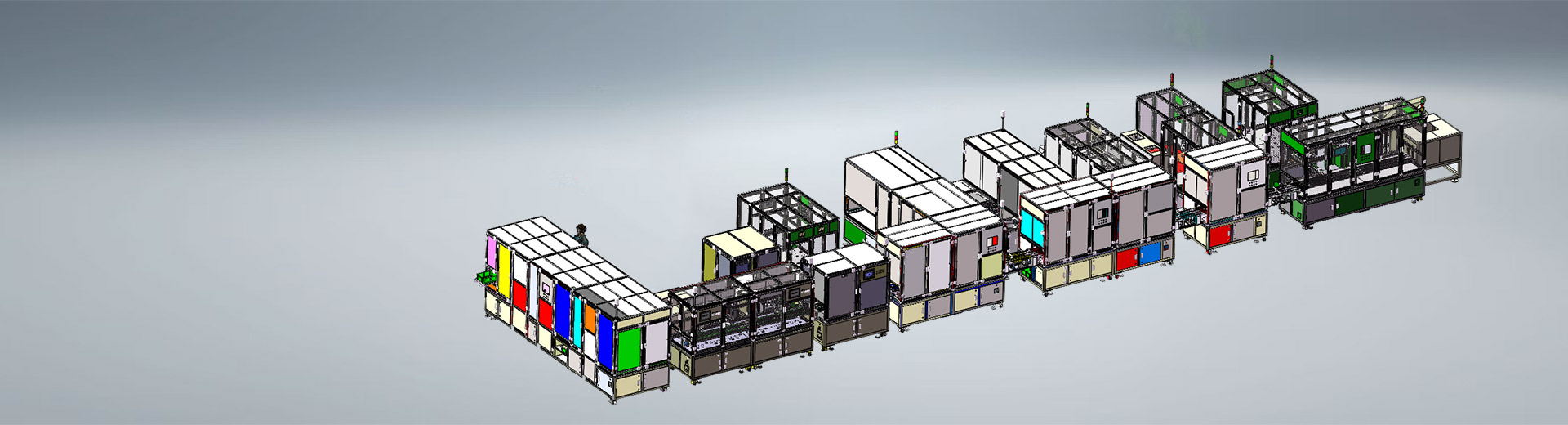

Fully Automatic Assembly Equipment

Semi-Automatic Automatic Moving Contact Assembly Equipment

Core Features

Automated assembly process

The equipment adopts advanced manipulator and carrier streamline design to realize full process automation from material handling to final assembly. The controller coordinates the actions of each link to ensure the efficiency and stability of the production process.

High-precision operation

The equipment supports the precise assembly of moving contacts and stationary contacts, ensuring good contact and smooth movement. Through optimized assembly process, the defective rate is reduced and the quality of finished products is improved.

Flexible customization capabilities

According to customer needs, the equipment can be customized and developed with functional modules to meet the production needs of different products. At the same time, the equipment supports offline manual operation mode, which is convenient for debugging and maintenance.

Intelligent monitoring and feedback

Equipped with a touch screen control display system, it monitors the production status in real time, supports automatic counting, alarm and other functions, and is easy to operate, suitable for novices to quickly get started.

Environmentally friendly and energy-saving design

The equipment adopts energy-saving pneumatic components and inverter control system to reduce energy consumption. It is also equipped with safety devices such as splash protection cover to ensure the safety of operators.

Technical features

Modular design: The equipment has a compact structure and a high degree of modularity, making it easy to maintain and upgrade.

High repeatability: The equipment has high repeatability, ensuring consistent quality of each batch of products.

Low maintenance cost: Standardized components are used to reduce maintenance difficulty and cost.

Application Scenario

This equipment is widely used in the production of low-voltage electrical appliances, switches and sockets, circuit breakers and other products. It is particularly suitable for moving contact assembly scenarios that require high precision and high efficiency.

English

English Español

Español