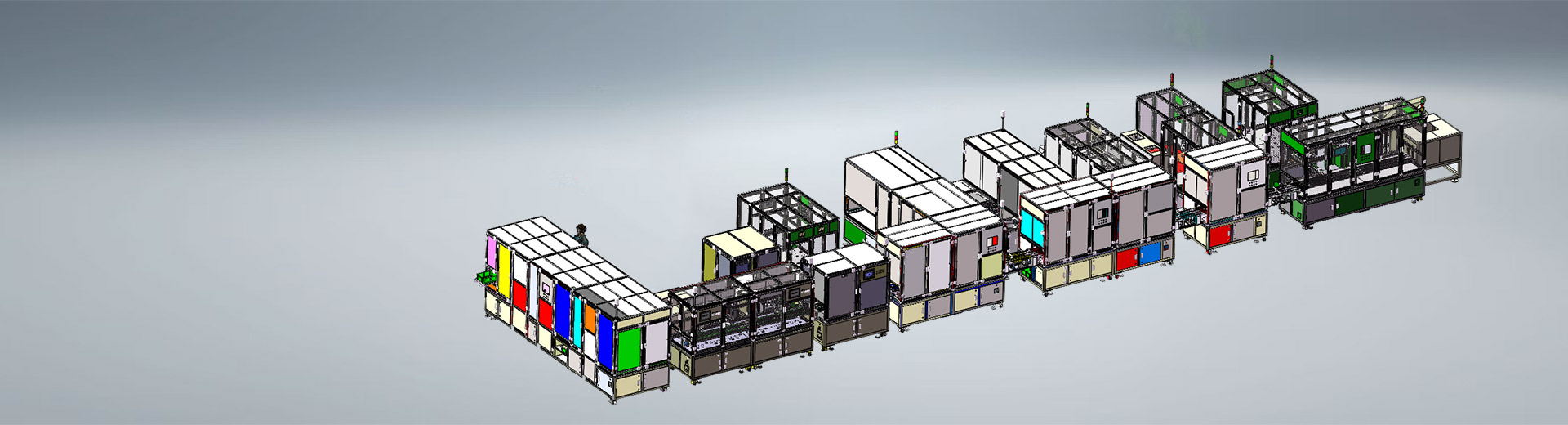

Fully Automatic Assembly Equipment

SPD Fully Automatic Assembly Equipment For Testing Flexible Production Line

Features :

Modular Design:SPDThe equipment adopts a modular design concept, which allows rapid adjustment and reorganization of functional modules according to different production needs, thus achieving flexible switching and efficient operation of the production line.

High degree of automation: The equipment integrates advanced automation technologies, including automatic loading and unloading, robotic gripping, precision detection and human-machine interaction interface, which can achieve a lossless and complete assembly process, significantly reduce manual intervention and improve production efficiency.

Flexible production:SPDThe equipment supports mixed-line production of various product types, can quickly adapt to changes in market demand, and meet the needs of small-batch, multi-variety production models.

Intelligent management: The equipment is equipped with an intelligent control system that can monitor the production status in real time, optimize the production rhythm, and issue timely warnings under abnormal circumstances to ensure the efficiency and stability of the production process.

Customized service: According to the personalized needs of different customers,SPDThe equipment can provide non-standard customization services to meet the high precision and complex process requirements of specific products.

High efficiency and energy saving: The equipment design focuses on energy efficiency optimization, adopts advanced energy-saving technology and modular configuration to reduce energy consumption and extend equipment service life.

Rapid deployment and maintenance:SPDThe equipment is easy to install, supports quick commissioning and maintenance, reduces downtime, and improves the overall operating efficiency of the production line.

English

English Español

Español