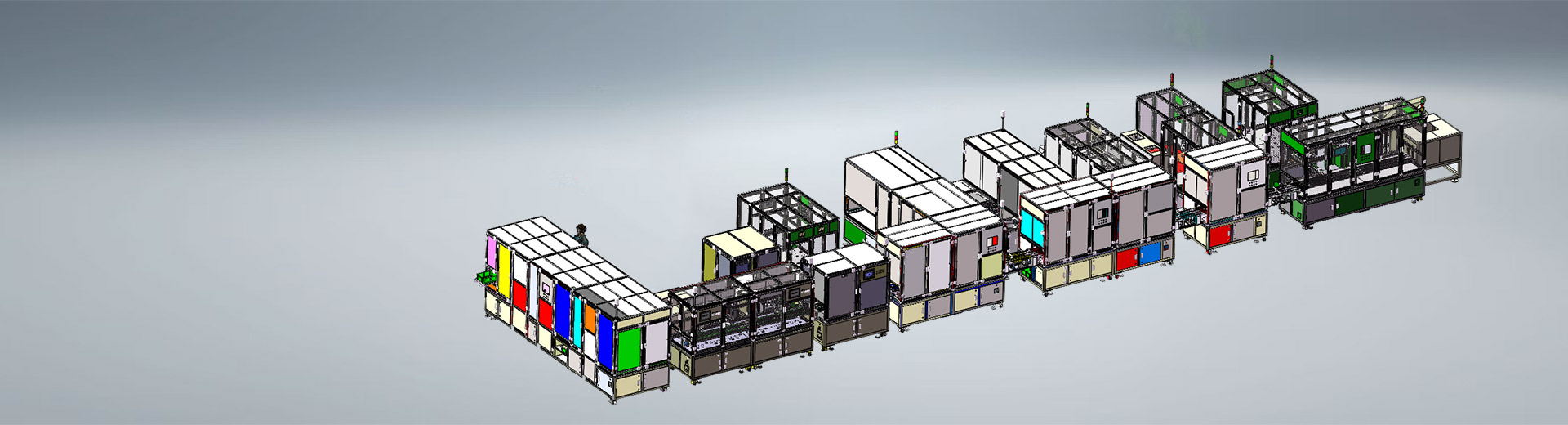

Magnetic Components Automated Welding Equipment

Automatic Welding And Assembly Equipment For Magnetic Components

The automatic welding and assembly equipment for magnetic components combines magnetic positioning technology and automated welding technology, which can realize the fast and precise assembly and welding of magnetic components. It is widely used in electronic components, automotive parts, communication equipment and other fields.

Core Features

Magnetic positioning and fixing: Use high-performance magnets and multi-angle positioning technology to ensure high-precision positioning and fixing of components during the assembly process, avoiding errors caused by manual operation.

Automatic welding: The equipment is equipped with a special welding module, which supports a variety of welding methods (such as spot welding, seam welding, etc.), with fast welding speed and high weld quality, and is suitable for magnetic components of different thicknesses and materials.

Efficient production: The equipment supports fully automated operation, reduces manual intervention, improves production efficiency, and reduces production costs.

Customized service: Provide personalized customization solutions according to customer needs, including equipment layout, function expansion, etc., to ensure that the equipment fully meets production needs.

Technical advantagesHigh-precision positioning: Multi-angle magnetic locator and triangulation positioning technology are used to ensure that the assembly accuracy meets industry standards.

Intelligent control system: The equipment is equipped with an advanced control system that supports online programming and real-time monitoring, and is easy to operate and maintain.

Energy saving and environmental protection: The equipment design focuses on optimizing energy efficiency, reducing energy consumption, and complying with the concept of green manufacturing.

Strong durability: Made of high-quality materials, the equipment has a stable structure, long service life, and can adapt to a variety of complex production environments.

Application

ScenarioElectronic component manufacturing: Applicable toledLamp beads,BGAWelding and assembly of electronic components such as chips.

Automobile parts production: used for the automated assembly of automotive electronic modules, sensors and other magnetic components.

Communication equipment assembly: supports precision welding and fixing of magnetic components in communication modules.

Key information:

Other main hardware: 5 cameras, 1 industrial computer; 1 6-axis robot.

Equipment size: 21000*4000mm.

Beat estimation: Whole line beat: ≤3.0s/pcs

English

English Español

Español