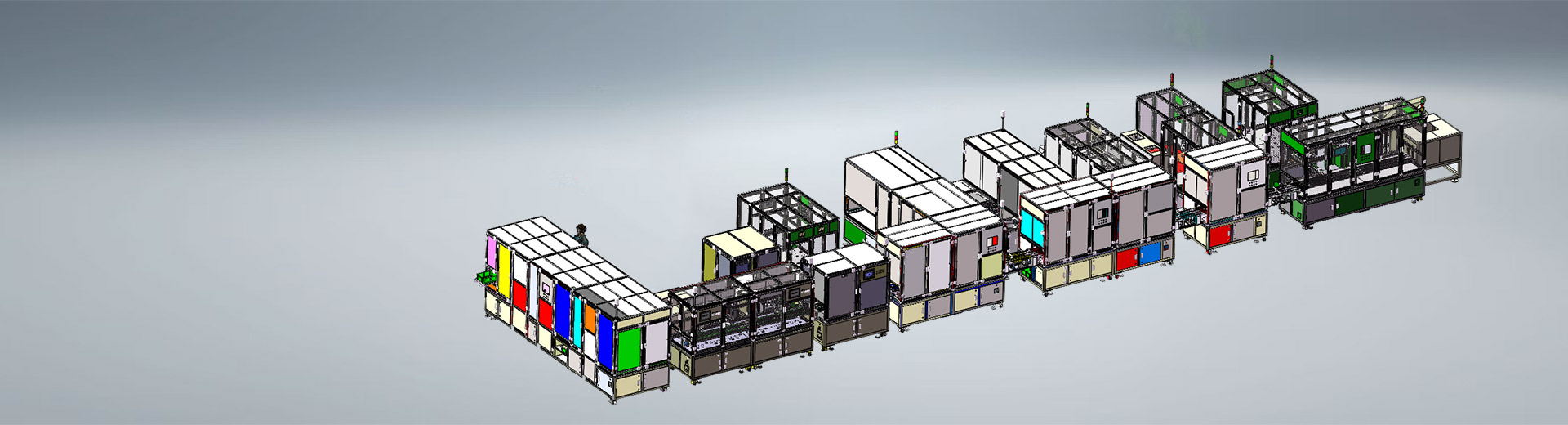

Neutral Parts Automated Welding Equipment

Neutral Components Automatic Welding Assembly Equipment

This project provides customers with a set of customized neutral component automated assembly and welding equipment. The equipment adopts vibration plate and coil automatic feeding technology. The accompanying tooling realizes the automated production process through the chain plate line and forklift mechanism assembly line, including assembly, welding, testing and unloading. The vibration plate uses the principle of electromagnetic vibration to arrange disordered workpieces in order and transport them to the next process, ensuring high-efficiency and high-precision production requirements. The equipment supports the production of products of various specifications and can adapt to different customer needs by replacing tooling, greatly improving production flexibility and efficiency. The equipment is also equipped with a complete testing system and data recording function to ensure the stable and reliable quality of the finished product. The entire system realizes the automation of the entire process from raw materials to finished products, significantly reducing labor costs and improving production efficiency and product quality. Fully automatic and highly efficient: The equipment adopts a fully automated production mode and can realize continuous cycle operation. It has more than 20 stations and ensures stable production efficiency and quality through precise process decomposition and time rhythm control. The equipment supports automatic feeding of multiple materials and has strong compatibility, further improving production flexibility and efficiency.

Intelligence and high precision: The equipment integrates welding technology, image detection technology, automatic feeding technology and high-precision assembly technology. It can monitor various process conditions and parameters in the production process in real time, and realize automatic identification and classification of finished products and unqualified products into storage through screen display. This intelligent design not only improves production efficiency, but also significantly reduces manual intervention and operating errors. Modularity and flexibility: The equipment adopts modular design, and its functions can be flexibly adjusted or upgraded according to production needs to adapt to the process requirements of different products. This design not only improves the applicability of the equipment, but also facilitates maintenance and expansion.

Stability and reliability: Precision fixtures and precise positioning technology are used during the operation of the equipment to ensure the stability and reliability of operation. The reliability of the mechanism design, the safety of the software control and the precise selection of electrical components all guarantee the long life and rapid repair of the equipment. Saving human resources: The equipment significantly reduces labor costs, for example, saving 20 workers in the third shift, while the work efficiency reaches 3 seconds/piece. This efficiency not only reduces production costs, but also improves the competitiveness of enterprises.

Innovation and patented technology: This equipment pioneered the automated assembly and welding of neutral parts, thermal components, and magnetic components in the low-voltage electrical industry, and has obtained an invention patent technology certificate (patent number: ZL 2018 2 1188175.x), reflecting its leading position in technological innovation.

Environmental protection and energy saving: The equipment adopts advanced energy-saving technology and environmentally friendly materials, reducing energy consumption and waste gas emissions, which is in line with the green trend of modern industrial development.

Key information:

Other main hardware: 5 cameras, 1 industrial computer; 1 6-axis robot.

Equipment main body size: 21000*4000mm.

Beat estimation: Whole line beat: ≤3.0s/pcs

English

English Español

Español