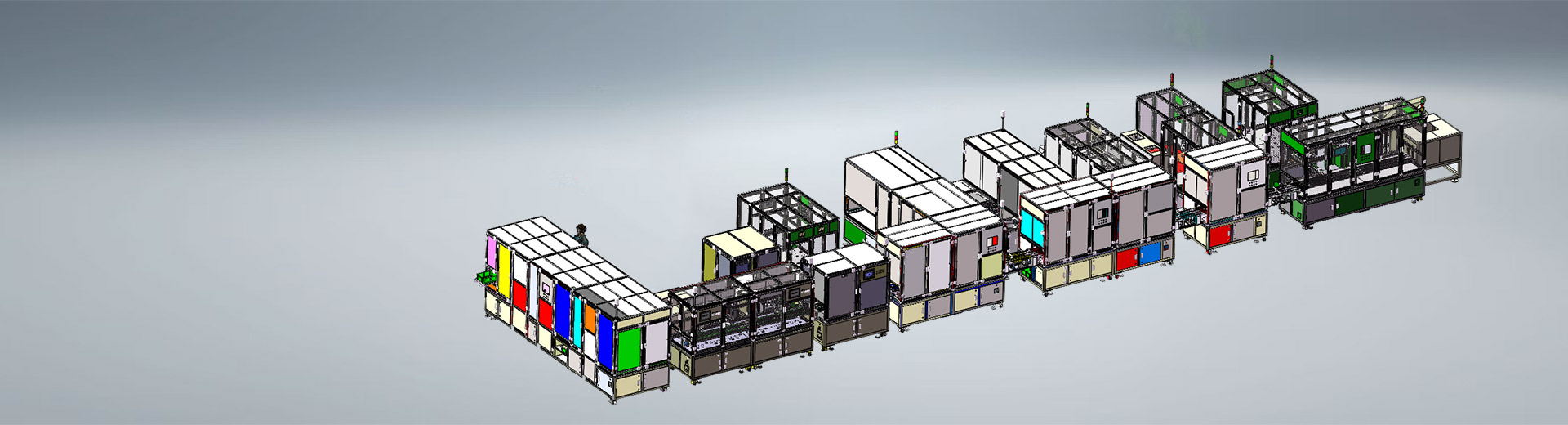

Thermal Components Automated Welding Equipment

Thermal Elements Automatic Welding Assembly Equipment

Our thermal component automatic welding and assembly equipment is an efficient and precise automation equipment specially designed for the welding and assembly of thermistors and related components. The equipment adopts advanced automation technology, combined with precise temperature control and mechanical structure, which can significantly improve production efficiency, reduce labor costs, and ensure the consistency and reliability of welding quality.

Core Features

The equipment is equipped with high-precision temperature sensors and heating modules, which can achieve millisecond-level temperature response speed (0.1s) to ensure temperature stability and uniformity during the welding process. Supports multiple welding modes, including hot air welding, dip soldering, etc., suitable for welding different types of thermistors and related components.

The equipment also supports multi-stage temperature rise control and displays the temperature curve in real time to ensure the transparency and controllability of the welding process. The equipment adopts a three-axis motion platform design, supports movement in the X/Y/Z directions, and can achieve fast positioning and efficient production.

The equipment supports large-capacity program storage, and users can write welding programs according to their needs to achieve rapid switching of diversified products. The device is equipped with an overheat protection function. When the temperature exceeds the set range, it will automatically stop working to avoid equipment damage or safety accidents. In addition, the equipment also has a fault alarm reminder function to ensure the continuity and safety of the production process.

The equipment is PLC controlled and equipped with a LCD display. Users can intuitively adjust welding parameters such as temperature, time, pressure, etc. through the touch screen. The equipment supports both manual and automatic operation modes to meet the needs of different production scenarios.

The equipment is widely used in electronic appliances, automotive parts, new energy batteries and other fields, and is particularly suitable for the following scenarios:

Thermistor welding: suitable for welding components such as NTC thermistors and PTC thermistors.

Battery assembly welding: used for welding of energy storage devices such as lithium batteries and square shell batteries.

Sensor assembly: suitable for mounting and welding of various sensors.

Key information:

Other main hardware: 5 cameras, 1 industrial computer; 1 6-axis robot.

Equipment main body size: 21000*4000mm.

Beat estimation: Whole line beat: ≤3.0s/pcs

English

English Español

Español